Those who are already working in the polished concrete market, and those who are just about to find their place in this market, may benefit from our 15 years of experience. In 2009-2010, everything was ground and polished only with heavy planetary machines.

But times are changing and polished concrete technology is advancing. Today on the market we see three technologies for the restoration of the old floor, which are used by professional contractors.

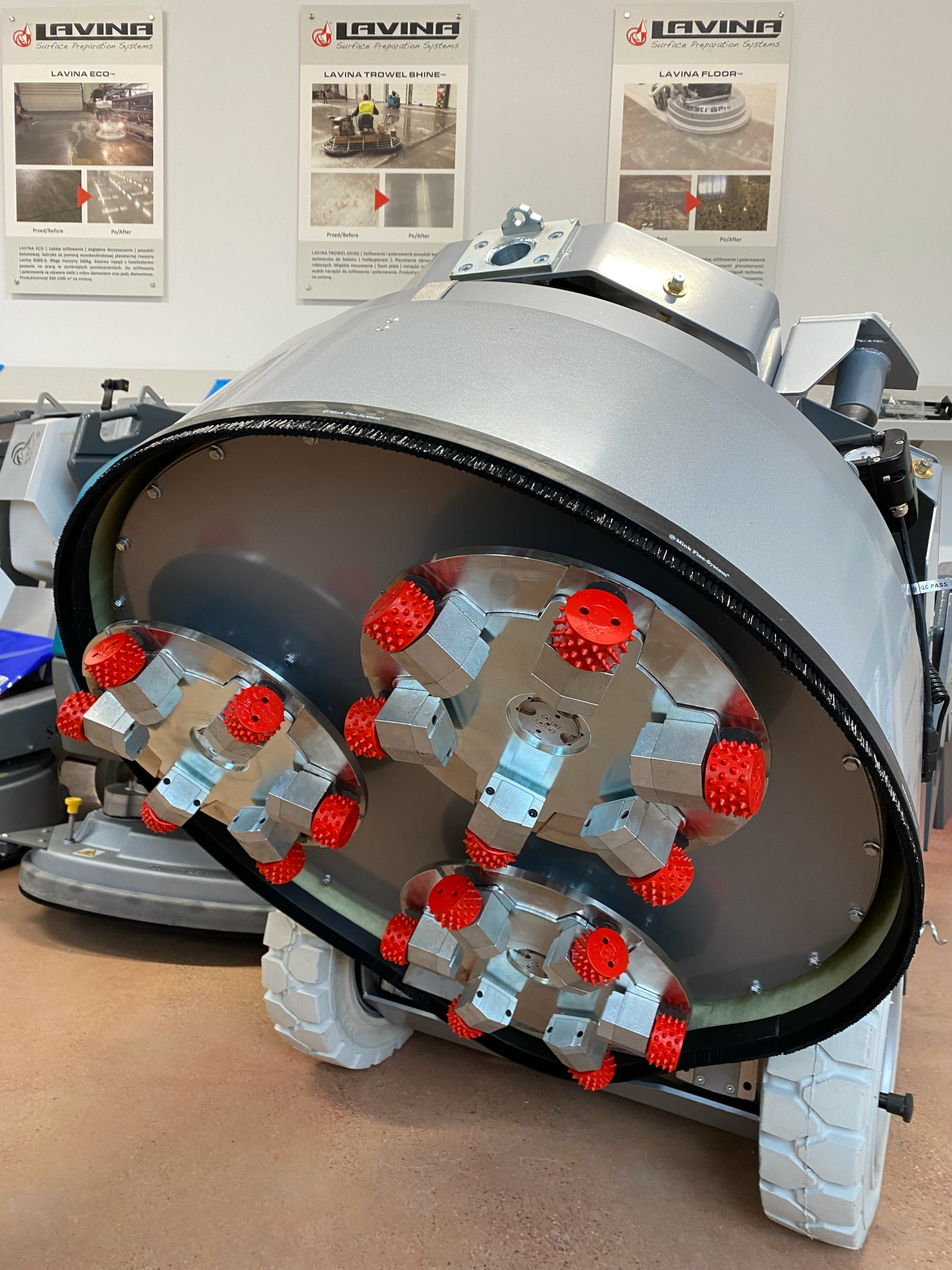

HEAVY GRINDING and POLISHING by planetary machine. This is a very high quality floor. Perhaps the only drawback is the high cost and low performance. This is the most expensive technology. However, if we are talking about stripping the adhesive and leveling, then most likely we will have to use several steps with a heavy machine.

POWER TROWEL GRINDING and POLISHING. This is the fastest technology with amazing quality effects. However, the tool manufacturer requires knowledge and experience in the production of diamond tools to ensure that the life of the tool and the surface finish match the weight of the machine and its technical capabilities.

LAVINA ECO HIGH SPEED is a new technology. Planetary grinding with diamond screens at high speeds with little pressure on the surface. Fast, convenient and economical to use, giving a fantastic result. Very popular on large projects where old industrial concrete floors need to be restored.

It cannot be argued that any technology is better or worse. It all depends on what quality of the surface we had “before” and what kind of floor we want to achieve “after”.

A competent and experienced contractor will always be able to combine several technologies on a specific project in order to satisfy the customer, in order to provide himself with the best way to grind and polish the surface.

.jpg)

-2.png)