Bush hammering of concrete and stone surfaces is becoming more and more popular. Fast, efficient and simple solution for planetary machines to make smooth concrete surfaces rough. What is it used for? Let`s take a look on a few examples:

1. There is a slippery concrete surface on the parking lot. A decision was taken to apply a polymer coating (paint) on a rough concrete or just lithium silicate to make it dustproof. But a special relief on the concrete surface is required, just such that the surface after applying the coating, silicate or paint remains rough.

2. It is necessary to remove 2-4 mm of hard topping coating on the concrete floor. It was decided to replace the toppings with polished concrete or polymer coating

3. Level the screed or non-solid concrete levels. It is necessary to remove 2-5 mm (even up to 1-2 cm) of non-solid concrete.

4. The architect designed the concrete pavement in public pedestrian areas, train stations, etc. or bush-hammered decorative concrete or stone coverings.

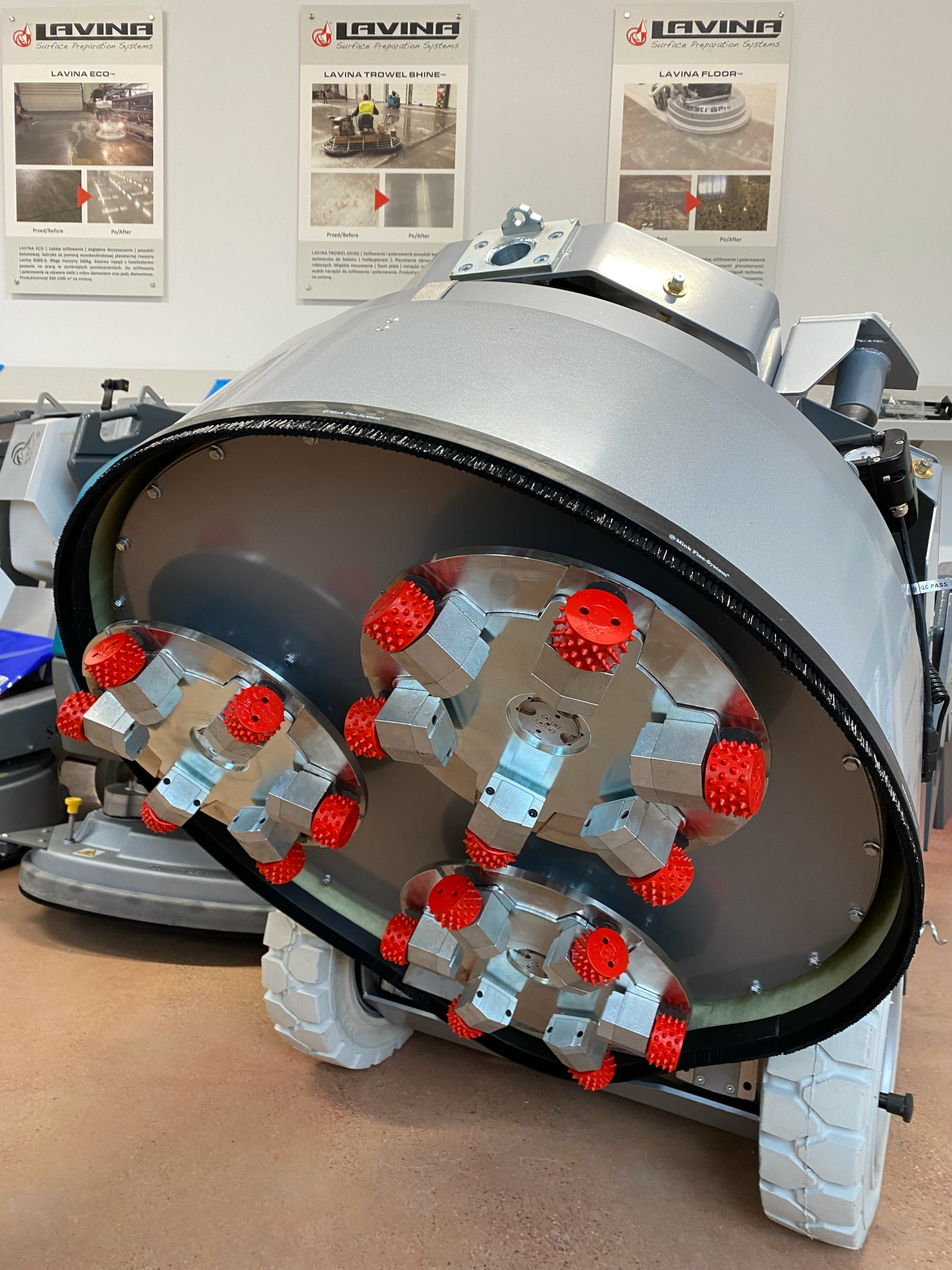

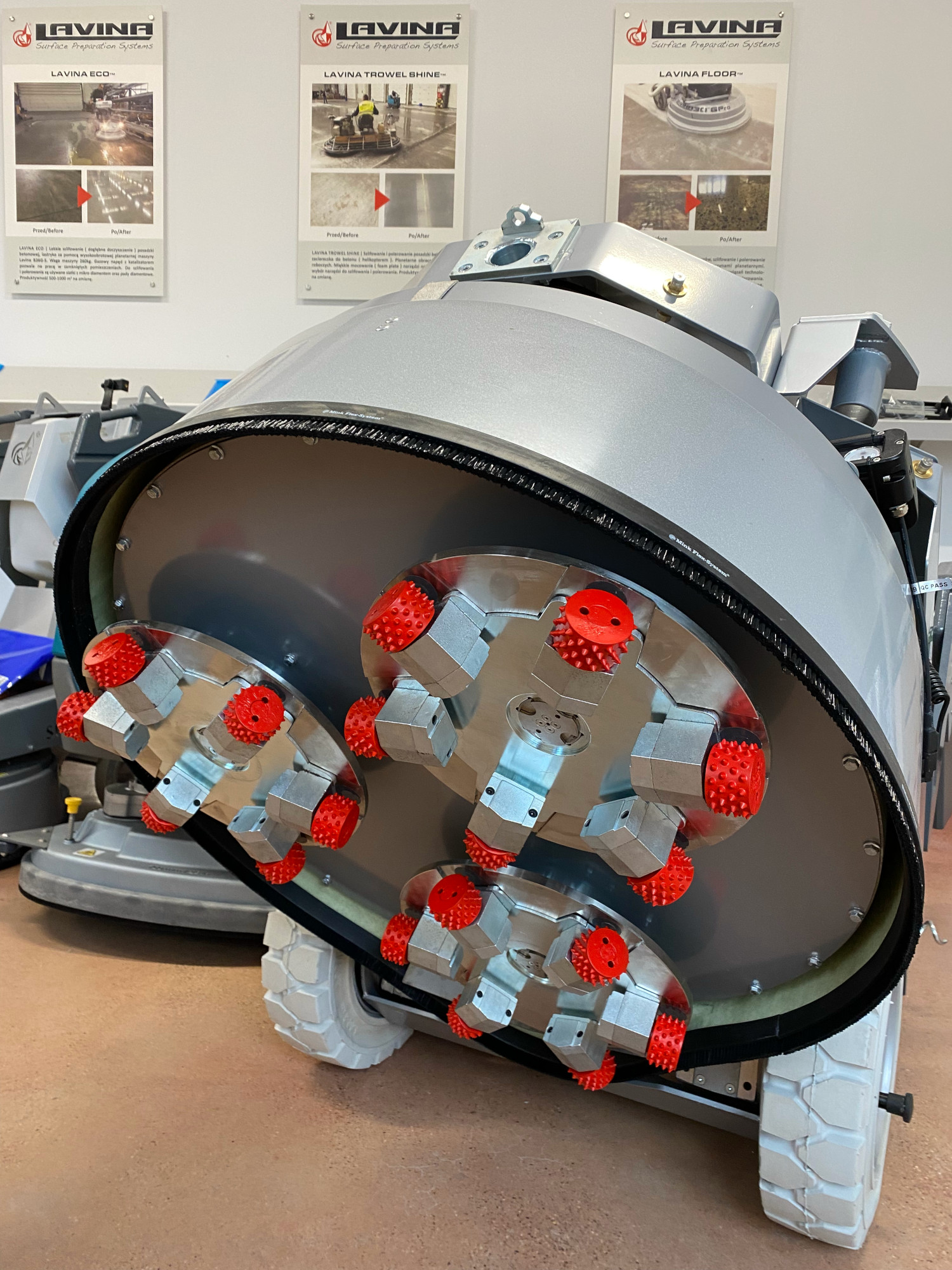

In all these cases, you can and should use a B-hammer mounted on a planetary grinder. The Bush hammer can be used with any Lavina model weighing from 65 to 720 kg. Here you will also find adapters to use B-hammer on planetary machines like Blastrac, HTC, Huscvarna, Scanmaskin, Schwamborn.

What should be kept in mind when working with the Bush hammers? B-hammer is a quick and easy solution that will allow you to make good money when using this solution. For example, using L25EU machine you can treat up to 200-400m2 with b-hammer tools per day if the work is properly organized. However, you are buying a fairly expensive tool kit and you should be well prepared.

- The harder the coating we want to process, the higher the wear on the Bush hammer will be.

- Not only the hardness of the surface affects the wear of the tool. The more uneven the surface, the higher the wear will be.

- It is also necessary to exclude shock loads on metal parts protruding from the surface (anchors, etc.). Large quantities of metal fiber will also increase tool wear.

- On large and medium sized projects, a test at the target location is mandatory to determine the surface quality and its abrasive properties. Such a test will help you choose the right type of Bush hammer, show the client the quality of the processed surface, and correctly calculate the number of tools for a specific object.

- Correct selection of revolutions and speed rate of the machine is important. An experienced operator will immediately determine the correct RPM and feed rate so that the tool will bush hammer (not grind) the surface.

- Wear of the tool will necessarily depend on the weight and parameters of the machine (as well as on the hardness and abrasiveness of the surface)

- Using a Bush hammer will always be more expensive than milling or shot blasting, but much faster.

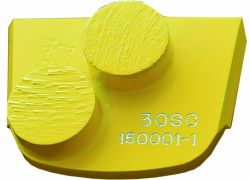

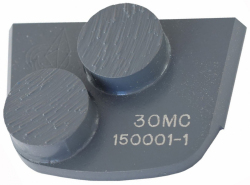

In our offer you will find several types of Bush hammers for different types of surfaces, for grinders of different weights as well as for different bush hammering depths.

.jpg)

-2.png)