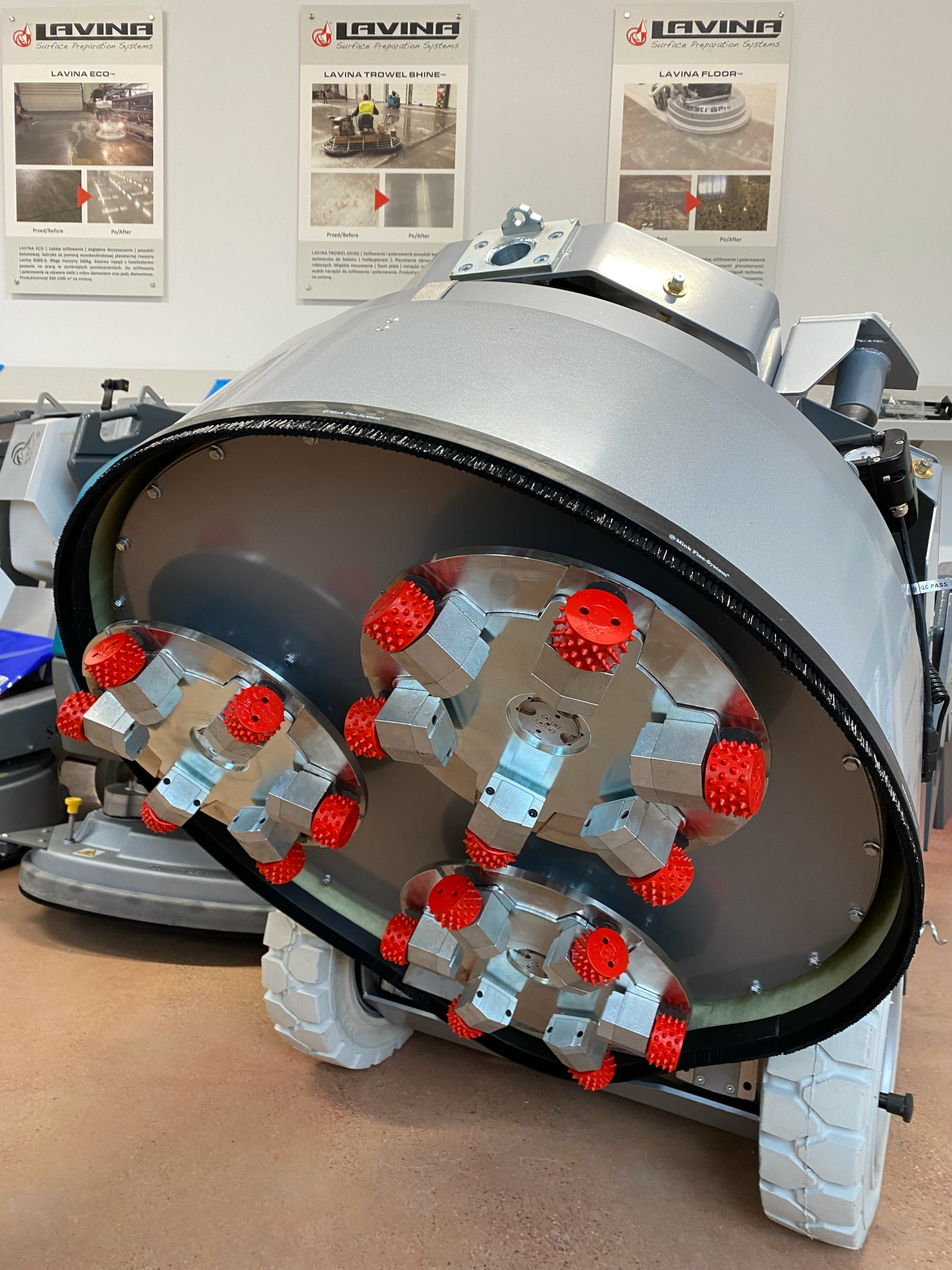

In grinding and polishing industry, work efficiency and tool prices are one of the key issues. A common question we receive from our customers is what are the differences between Superabrasive metal bond tools and so-called counterfeits?

Currently, approximately in every industry you can meet the so-called "Fakes". The polished concrete industry has been defending itself against them for a long time, but the time has come that Chinese companies have noticed this industry as well. We will try to provide information concerning working with Chinese tools collected directly from several of our clients who, after trying non-original tools, returned to work with original tools.

When buying a machine from China, the matter is much simpler, there is a lower price, but there are difficulties like high transport costs, often very difficult access to spare parts and the lack of service in Poland.

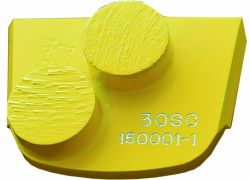

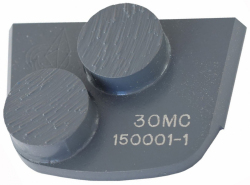

With tools, things are a bit different, because they are easier to transport and have less value. However, our clients tell us that Chinese products lack one thing that is very important from a business point of view - repeatability and quality. There are batches of tools that meet customer requirements, but the next delivery turns out to have a different diamond concentration in the grinding segments, which causes an unpleasant surprise. Original tools ensure repeatability and maintain the appropriate quality of the product, in particular, it is worth emphasizing the fact that Superabrasive itself produces artificial diamonds for its tools and it is not dependent on sub-suppliers.

The issue of quality and repeatability is also important in terms of the dimensions themselves. Unfortunately, the tools are not always perfectly matched and it happens that they do not fit or plug into the Quickchange holder.

Finally, the same applies to the quality of grinding and bonding. Original tools, despite the higher price, have a much higher performance. Some say that a worse batch of Chinese tools can be worn off after 200 meters of the floor!

The choice of the tool is of course made by the customer, but we recommend that you choose proven tools that require less downtime to replace the segment.

.jpg)

-2.png)