Blog categories

Categories

- 555 Machines rental

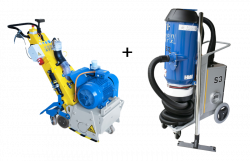

- Equipment + vacuum cleaners

- Floor Grinders and Polishers

- Scarifiers, shavers and accessories

- Floor scrapers, accessories

- Diamond, PCD Tools

- Diamond Pads, Screens

- Hand Grinders and Tools

- Industrial Dust Extractors

- Densifaers, Sealers and dyes

- Power Trowel Grinding and Polishing

- Power Trowels, Pans and Blades

- Diamond floor cutting

- Polished Concrete Sample

- Beton555 Sale

- 555 Workshops

Blog

- Amano Pioneer Eclipse 17.02.2022

- Instrukcja nakładania barwników 07.10.2021

Manufacturer

Bestsellers

- 15 601,14 EUR 15 601,14 EUR Nett /post-tax

- 5 627,27 EUR 5 627,27 EUR Nett /post-tax

- from 38,41 EUR from 38,41 EUR Nett /post-tax

- from 29,55 EUR from 29,55 EUR Nett /post-tax

- from 52,35 EUR from 52,35 EUR Nett /post-tax

- from 144,79 EUR from 144,79 EUR Nett /post-tax

- 28,43 EUR 28,43 EUR Nett /post-tax

- 102,55 EUR 102,55 EUR Nett /post-tax

- 15 601,14 EUR 15 601,14 EUR Nett /post-tax

- 5 627,27 EUR 5 627,27 EUR Nett /post-tax

- from 38,41 EUR from 38,41 EUR Nett /post-tax

- from 29,55 EUR from 29,55 EUR Nett /post-tax

- from 52,35 EUR from 52,35 EUR Nett /post-tax

- from 144,79 EUR from 144,79 EUR Nett /post-tax

- 28,43 EUR 28,43 EUR Nett /post-tax

- 102,55 EUR 102,55 EUR Nett /post-tax

- 15 601,14 EUR 15 601,14 EUR Nett /post-tax

Recently added

- 26 795,45 EUR 32 958,41 EUR 26 795,45 EUR Nett /post-tax

- 15 659,09 EUR 19 260,68 EUR 15 659,09 EUR Nett /post-tax

- 14 522,73 EUR 17 862,95 EUR 14 522,73 EUR Nett /post-tax

- 1 125,00 EUR 1 383,75 EUR 1 125,00 EUR Nett /post-tax

- 77,27 EUR 95,05 EUR 77,27 EUR Nett /post-tax

- 6 795,45 EUR 8 358,41 EUR 6 795,45 EUR Nett /post-tax

- 6 113,64 EUR 7 519,77 EUR 6 113,64 EUR Nett /post-tax

- 1 911,82 EUR 2 351,54 EUR 1 911,82 EUR Nett /post-tax

- 26 795,45 EUR 32 958,41 EUR 26 795,45 EUR Nett /post-tax

- 15 659,09 EUR 19 260,68 EUR 15 659,09 EUR Nett /post-tax

- 14 522,73 EUR 17 862,95 EUR 14 522,73 EUR Nett /post-tax

- 1 125,00 EUR 1 383,75 EUR 1 125,00 EUR Nett /post-tax

- 77,27 EUR 95,05 EUR 77,27 EUR Nett /post-tax

- 6 795,45 EUR 8 358,41 EUR 6 795,45 EUR Nett /post-tax

- 6 113,64 EUR 7 519,77 EUR 6 113,64 EUR Nett /post-tax

- 1 911,82 EUR 2 351,54 EUR 1 911,82 EUR Nett /post-tax

- 26 795,45 EUR 32 958,41 EUR 26 795,45 EUR Nett /post-tax

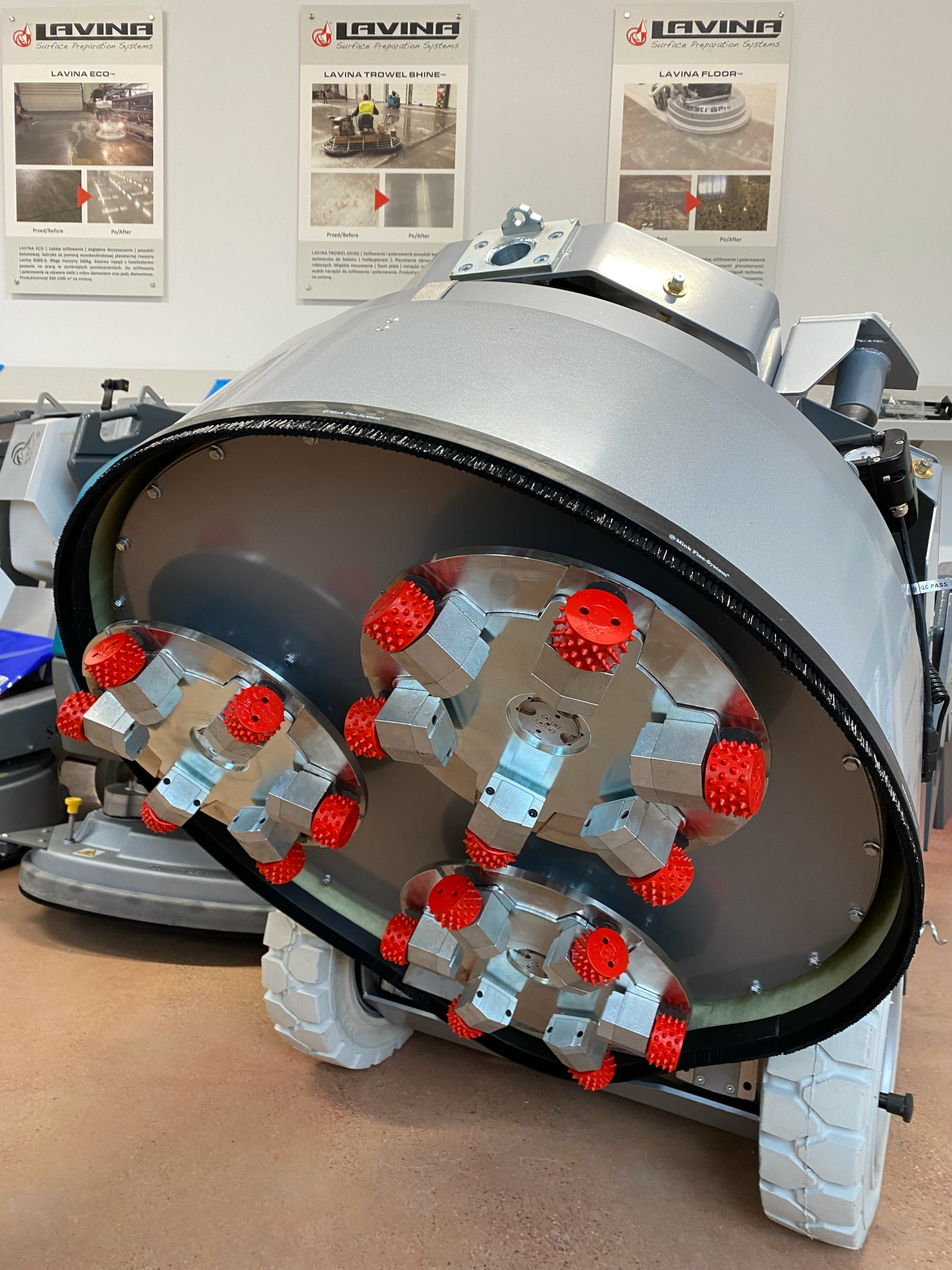

CONCRETE GRINDING WITH POWER TROWEL

TROWEL SHINE metal head is attached directly on the trowel pan using four screws. Tools attachment is very quick and easy. Protective plate which blocks diamond segments, is attached after metal diamond tools are mounted on a TROWEL SHINE head. SEE VIDEO

When mounted on a trowel pan, one TROWEL SHINE head is mounted under each trowel blade. If trowel pan has 4 mounts for 4 blades, you need to put 4 metal TROWEL SHINE heads.

Grinding with a power trowel using metal diamond tools is only possible on double power trowel machines 2/900mm, 2/1200mm, 2/1500mm, 2/1600mm. Under each trowel blade there is one metal TROWEL SHINE head.

Do not use metal segments when grinding with TROWEL SHINE metal heads on single disc trowels.

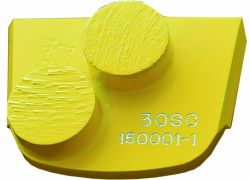

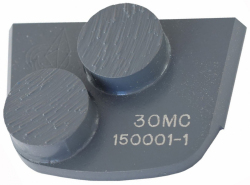

You can also use different types and grids of metal diamond XQC tools for grinding concrete floors of different hardness. MC segments (for medium hard concrete) are used for industrial concrete floors or SC segments (non-hard concrete surfaces and surfaces with problems after pouring or drying concrete).

Grits 0030 -0050 -0070 0120 . 30 grit - aggressive grinding. 120 fine grinding.

To eliminate visible scratches on concrete floor after grinding with metal segments (honing) use XQCHDCO copper tools : 50-100-200 grit.

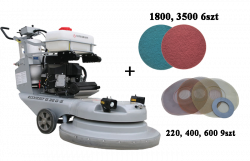

To polish concrete with TROWEL SHINE heads for high gloss you can use polishing tool XQC13WF grits from 50 to 3500 grit.

Grinding with metal segments is done with WATER only! You will need a floor scrubber for cleaning wet concrete slurry. Floor should be cleaned after

each step (grit) of the diamond tool.

Honing with XQCHDCO Cooper tools is performed with water ONLY!

For more information and advice CONTACT US

-2.png)