VonArx Scarifiers and Shavers – Swiss Precision in Concrete and Asphalt Processing

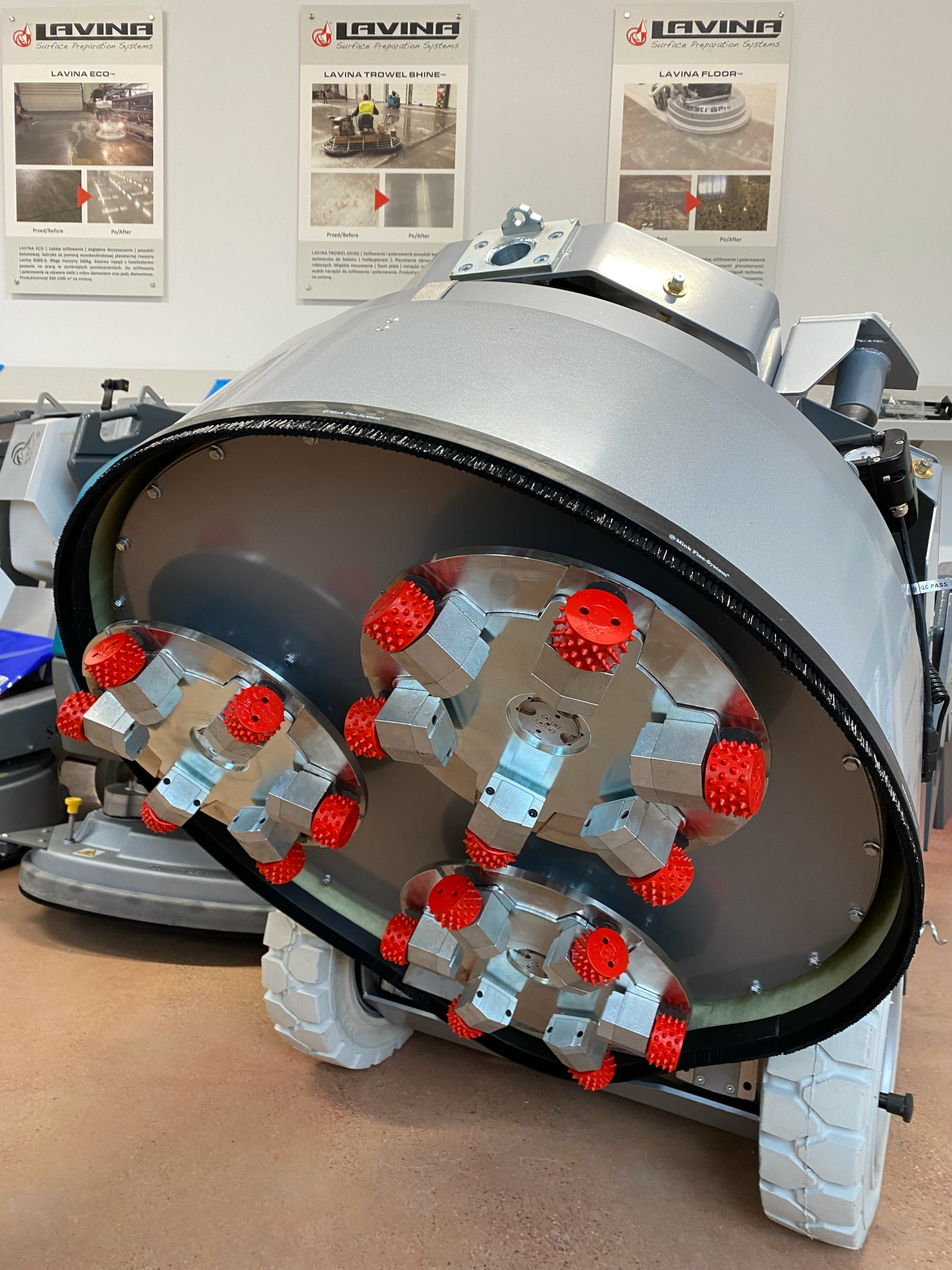

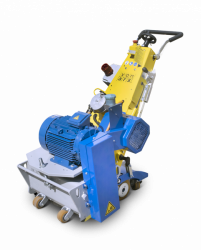

Looking for reliable scarifiers and shavers for concrete or asphalt? Choose VonArx machines – a Swiss brand with years of experience, trusted by professionals around the globe. VonArx scarifiers deliver solid construction, high performance, and precise results – even under the toughest conditions.

Why choose VonArx scarifiers and shavers?

VonArx is renowned for its innovative surface preparation technology. Their concrete scarifiers and shavers for asphalt and industrial floors are perfect for both renovation projects and surface preparation before applying new coatings.

Key advantages of VonArx equipment include:

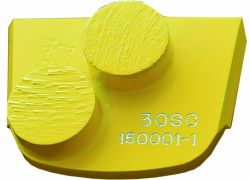

- High power and efficiency – ideal for removing old coatings, adhesives, paints, and resins

- Adjustable cutting depth – for precise control of the work process

- Robust construction – built to withstand heavy-duty use

- Ease of use and mobility – ergonomic design simplifies transport and operation on site

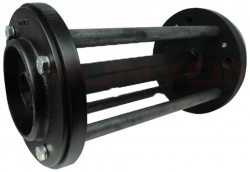

Popular VonArx Scarifier Models

VonArx offers machines such as:

- VonArx VA 30SH – a versatile machine for medium and large surfaces

- VonArx FR 200 – a popular shaver for removing markings and surface contaminants from asphalt

Where to Buy VonArx Scarifiers in Poland?

We are the official distributor of VonArx machines in Poland. We offer sales, service, and expert technical support. Looking for a specific model? Contact us – we’ll help you find the right VonArx scarifier or shaver tailored to your needs.

.jpg)

-2.png)