Grinding and polishing of marble must be done with a special method that will not leave scratches on the surface. Scratches occur when the tools with the metal bond are incorrectly selected. To avoid this problem, try grinding and polishing the surface in the target area. Working on marble surfaces requires appropriate knowledge and experience. Unevenly arranged marble tiles, old marbles, require heavy grinding on planetary grinding machines. In order to obtain a suitable surface after using metal-bonded tools, it is recommended to use plastic-bonded tools with gradations of 50, 100, 200, 400, 800 for honing and scuffing microcracks and mechanical polishing. After 800 grit, the marble surface usually gains a slight gloss and is ready for further work. Then apply polishing powders or a liquid crystallizer together with a diamond pad or steel fiber. The crystallizer and powders serve to increase the hardness of the treated surface. The final stage of works is to protect the surface with the final impregnation. Very often the final impregnation needs to be rubbed off by a high-speed machine with a soft pad (e.g. containing horsehair).

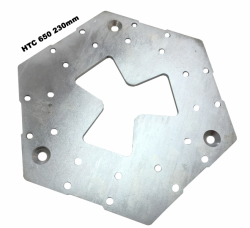

L30ES7

L25LES7

L25ES7

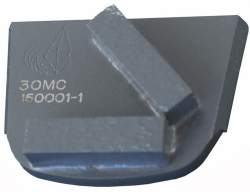

X2S-MC

-2.png)