Polished concrete

To begin with, our 12 years of experience in the industry, hundreds of successfully completed projects by Lavina contractors, millions of square meters of polished concrete made, allowed us to classify technologies:

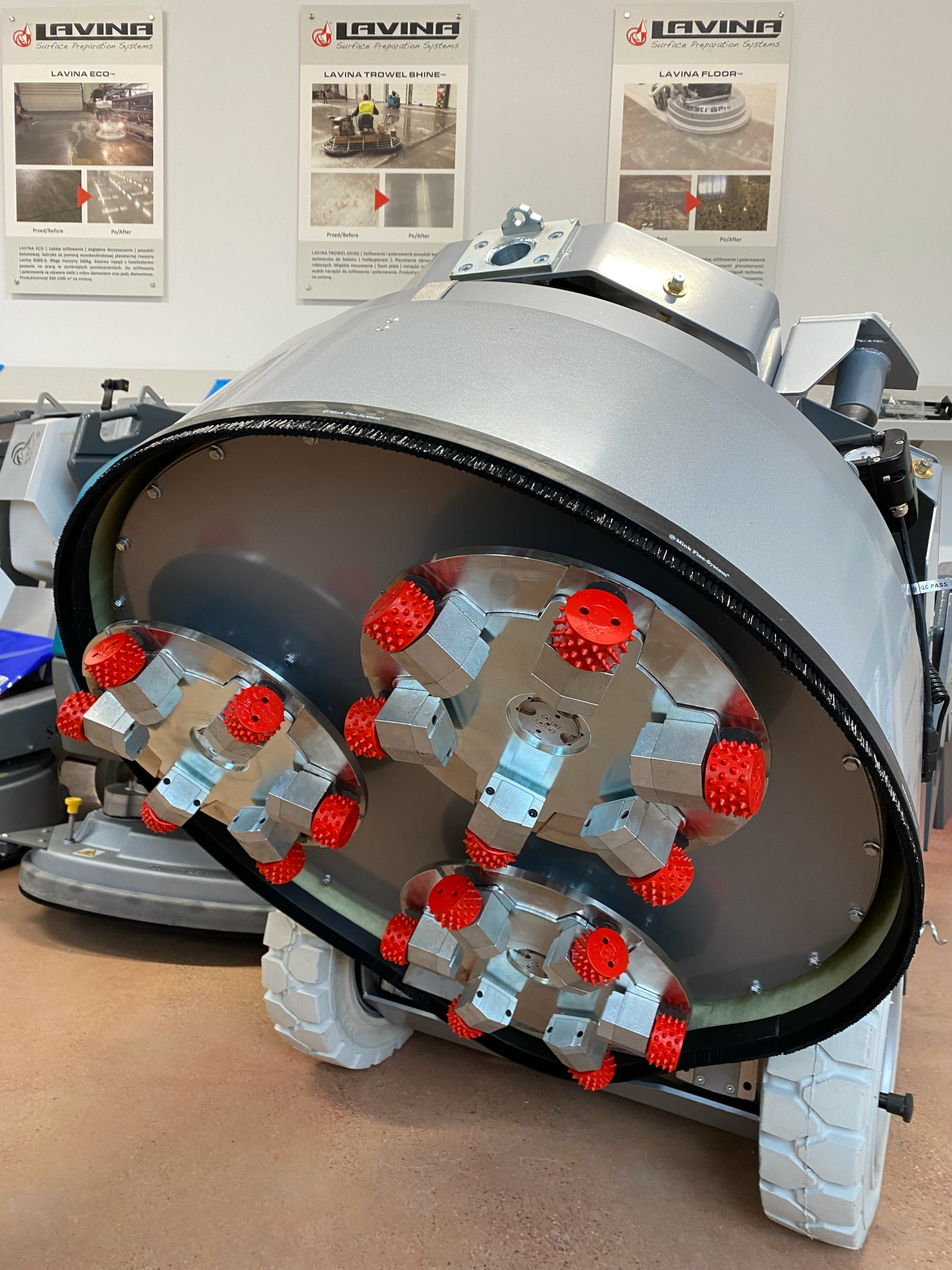

- Grinding polishing with a heavy planetary machine (Lavina Floor)

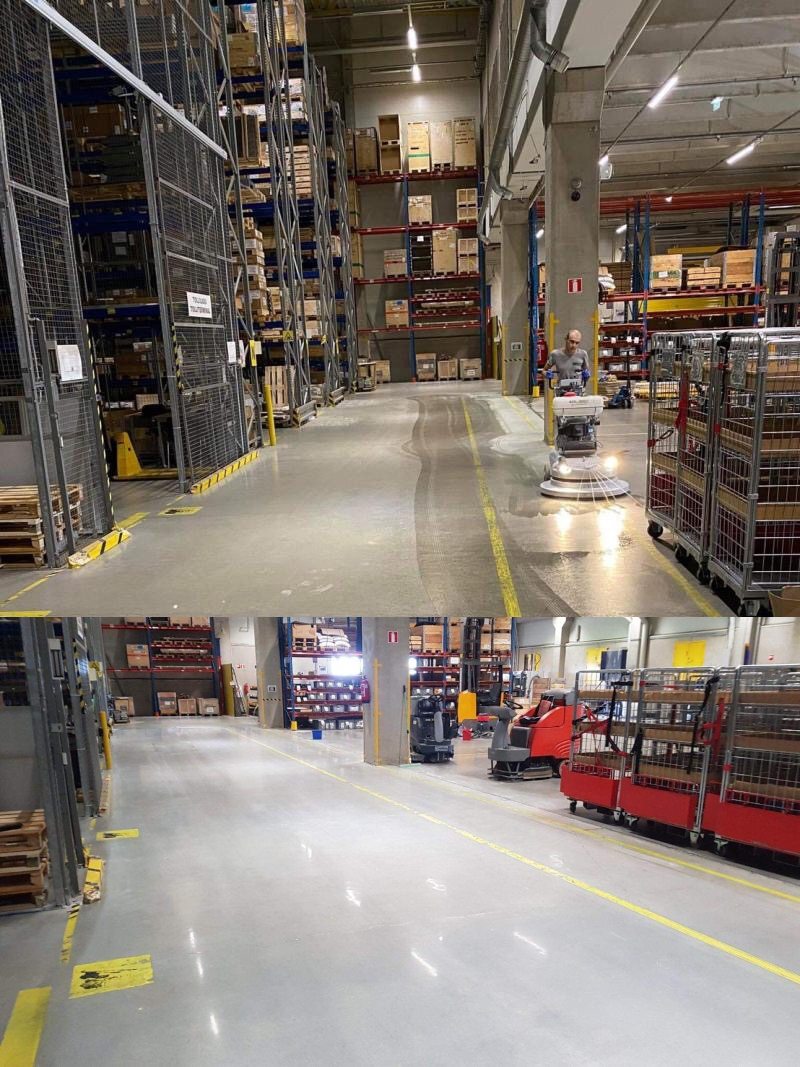

- Grinding polishing with a three-head high-speed machine (Lavina ECO)

- Grinding polishing with a ‘helicopter’ (Trowel Shine)

- Grinding polishing with a scrubber (Shine Pro)

A number of contractors will be surprised, but our observation of our partners reveals that the most successful are those who know how to effectively select technology for a specific project and for a specific budget. To perform work just like the customer demands. No better or worse.

Operating in richer and more developed markets, Americans and Western Europeans are bound to make two theses:

First - grinding and polishing with heavy planetary machine gives the best concrete surface quality.

Second - all other technologies are not suitable for making polished concrete.

We do agree with the first thesis, however, We disagree with the second one. Polished concrete is always mechanical surface treatment + chemical hardening and surface protection.

The question is: what contractor should do if the customer pays 4-5 Euro for 1m2? Not a penny more, not a penny less! The client does not need Gloss 90. 55 is quite enough, and the level of porosity of the surface DOI must be at 50.

Additionally, it is required to complete 15K-20K m2 in 2-3 weeks? Here, in Eastern Europe, these are the prices for grinding and polishing on large objects.

Polished concrete myths:

1. It is possible and necessary to accustom the client to just only one technology of grinding and polishing with heavy machine. This opinion is extremely popular in countries where prices for polished concrete are high. But nowadays, in a difficult market situation, the Customer will never allow you to stay for 2-4 months on a large project and perform 100-200 m2 per day using heavy machine.

2. A heavily polished floor will ALWAYS remain in an excellent condition. While polishing using any other technology will quickly lose its appearance and surface quality.

We cannot agree with this. Any polished concrete will become unusable if not treated accordingly. Daily or at least periodic surface cleaning (if done correctly) will ALWAYS keep the polished concrete in excellent condition and will allow it to gain hardness every year.

What is more, there is another myth in this business - you can completely abandon heavy and expensive planetary machines and just stick to high-speed machines or ‘helicopters’.

This is not true! Not being able to remove old materials (glue or polymers), not having the ability to qualitatively level and deeply sand concrete surfaces will eventually make you uncompetitive in this business.

All in all, there are neither good nor bad concrete technologies. There are very different projects and various end customers (clients).

Once again, We wish strong health and great success in business to everyone!

Heavy planetary grinder

Trowel Shine technology

Lavina Eco technology

.jpg)

-2.png)