Polished Concrete – Durable and Aesthetic Concrete Flooring

Polished concrete is the most logical and durable solution for concrete flooring in medium and large commercial, industrial, and public utility projects. Thanks to mechanical surface treatment – without any top coating – polished concrete stands out with exceptional durability, abrasion resistance, and aesthetic appearance.

How is polished concrete made?

The process of creating polished concrete involves several stages:

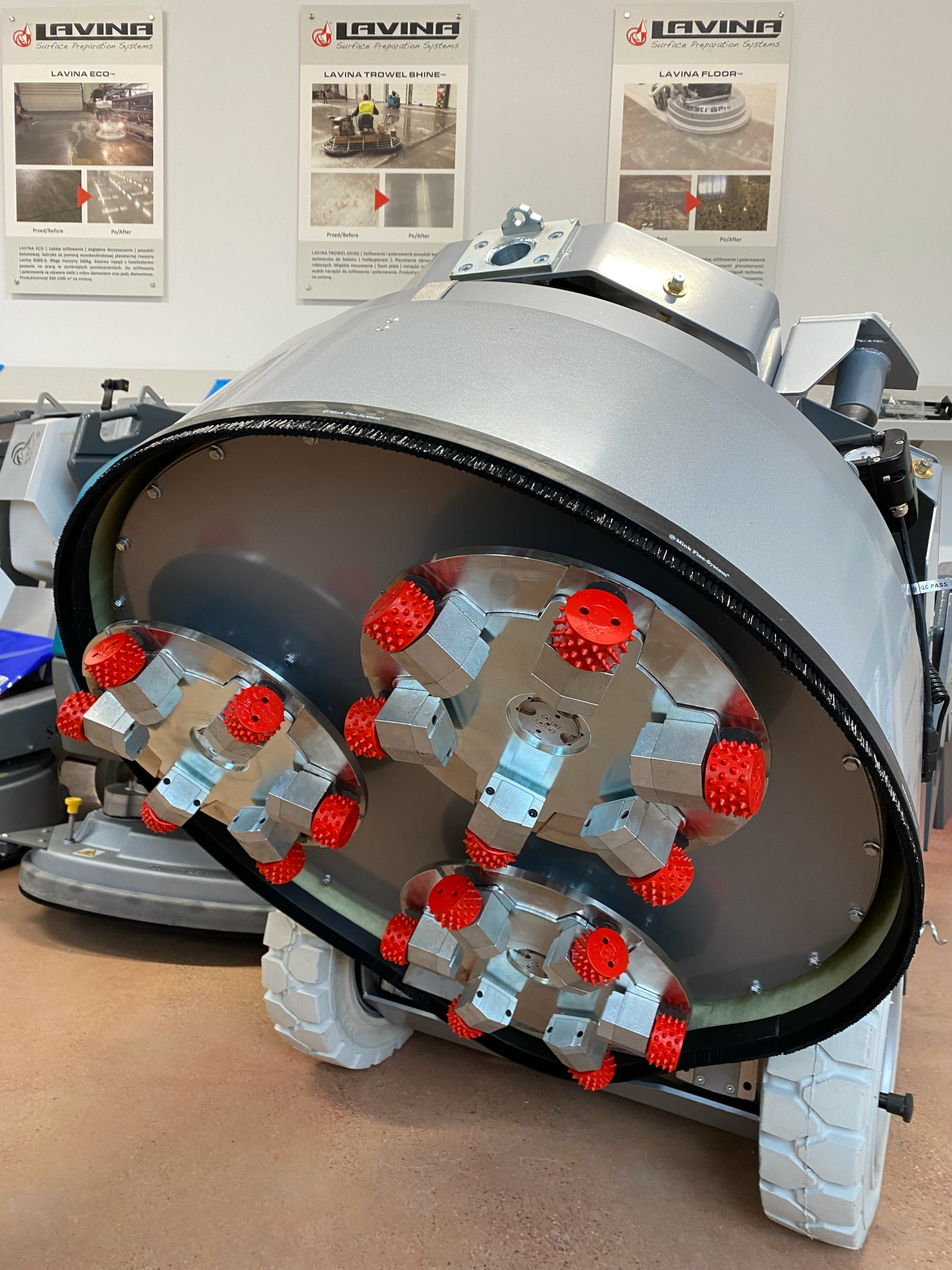

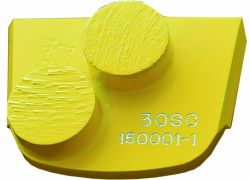

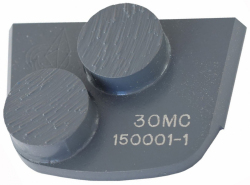

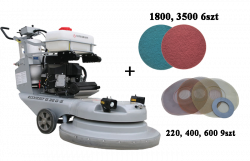

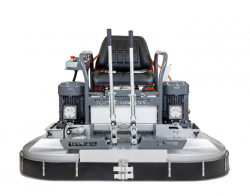

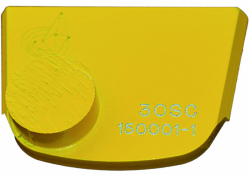

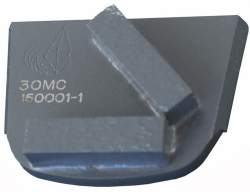

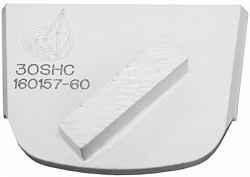

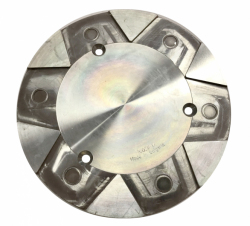

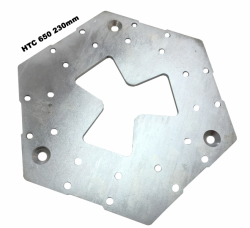

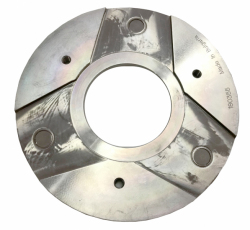

- Grinding the concrete is done using planetary grinders and metal-bond diamond tools of various grits.

- Then the surface is hardened with special silicate-based chemicals.

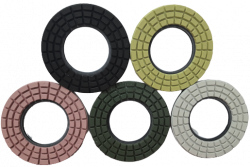

- The next step is surface polishing using polymer-bond diamond tools of gradually higher grits.

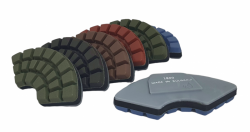

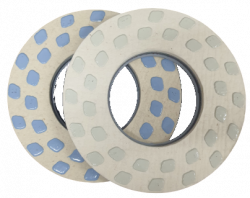

- The final stage is finishing and shining, performed with diamond pads or special polishing discs.

- The entire surface is protected with high-quality concrete impregnators that increase resistance to water, stains, and industrial chemicals.

The result is a high-gloss concrete floor with excellent durability and low maintenance costs.

Why choose polished concrete?

- no coatings or resins – nothing flakes or peels

- long-term durability – abrasion, trolley, and chemical resistance

- low operating costs and easy to keep clean

- aesthetics – surface from matte to high gloss

- sustainable solution – zero waste, zero VOCs

Polished concrete – not just technology, but also business

Polished concrete is also a profitable business that is rapidly growing in Poland and across Europe. Investment in professional equipment, diamond tools, and technological knowledge is a chance for high-margin services and a quick return on investment.

L30ES7

L25LES7

L25ES7

X2S-MC

-2.png)