Blog categories

Categories

- 555 Machines rental

- Floor Grinders and Polishers

- Power Trowels, Pans and Blades

- Power Trowel Grinding and Polishing

- Scarifiers, shavers and accessories

- Shotblasting machines, accessories

- Dust extractors for shot blasting machines

- Floor scrapers, accessories

- Dust Extractors, pre-separators

- Equipment + vacuum cleaners

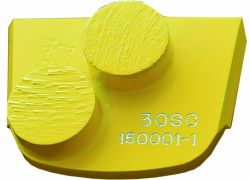

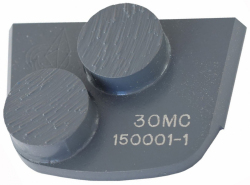

- Diamond, PCD Tools

- Diamond Pads, Screens

- Hand Grinders and Tools

- Densifaers, Sealers and dyes

- Diamond floor cutting

- Polished Concrete Sample

- 555 Workshops

- Beton555 Sale

Blog

- Amano Pioneer Eclipse 17.02.2022

- Instrukcja nakładania barwników 07.10.2021

Manufacturer

Bestsellers

- 5 627,27 EUR 5 627,27 EUR Nett /post-tax

- from 38,41 EUR from 38,41 EUR Nett /post-tax

- from 29,55 EUR from 29,55 EUR Nett /post-tax

- from 52,35 EUR from 52,35 EUR Nett /post-tax

- from 144,79 EUR from 144,79 EUR Nett /post-tax

- 28,43 EUR 28,43 EUR Nett /post-tax

- 15 601,14 EUR 15 601,14 EUR Nett /post-tax

- from 65,10 EUR from 65,10 EUR Nett /post-tax

Recently added

- 8 650,00 EUR 10 639,50 EUR 8 650,00 EUR Nett /post-tax

- 25 900,00 EUR 31 857,00 EUR 25 900,00 EUR Nett /post-tax

- 25 900,00 EUR 31 857,00 EUR 25 900,00 EUR Nett /post-tax

- 19 975,23 EUR 24 569,53 EUR 19 975,23 EUR Nett /post-tax

- 19 870,00 EUR 24 440,10 EUR 19 870,00 EUR Nett /post-tax

- 13 405,00 EUR 16 488,15 EUR 13 405,00 EUR Nett /post-tax

- 14 275,00 EUR 17 558,25 EUR 14 275,00 EUR Nett /post-tax

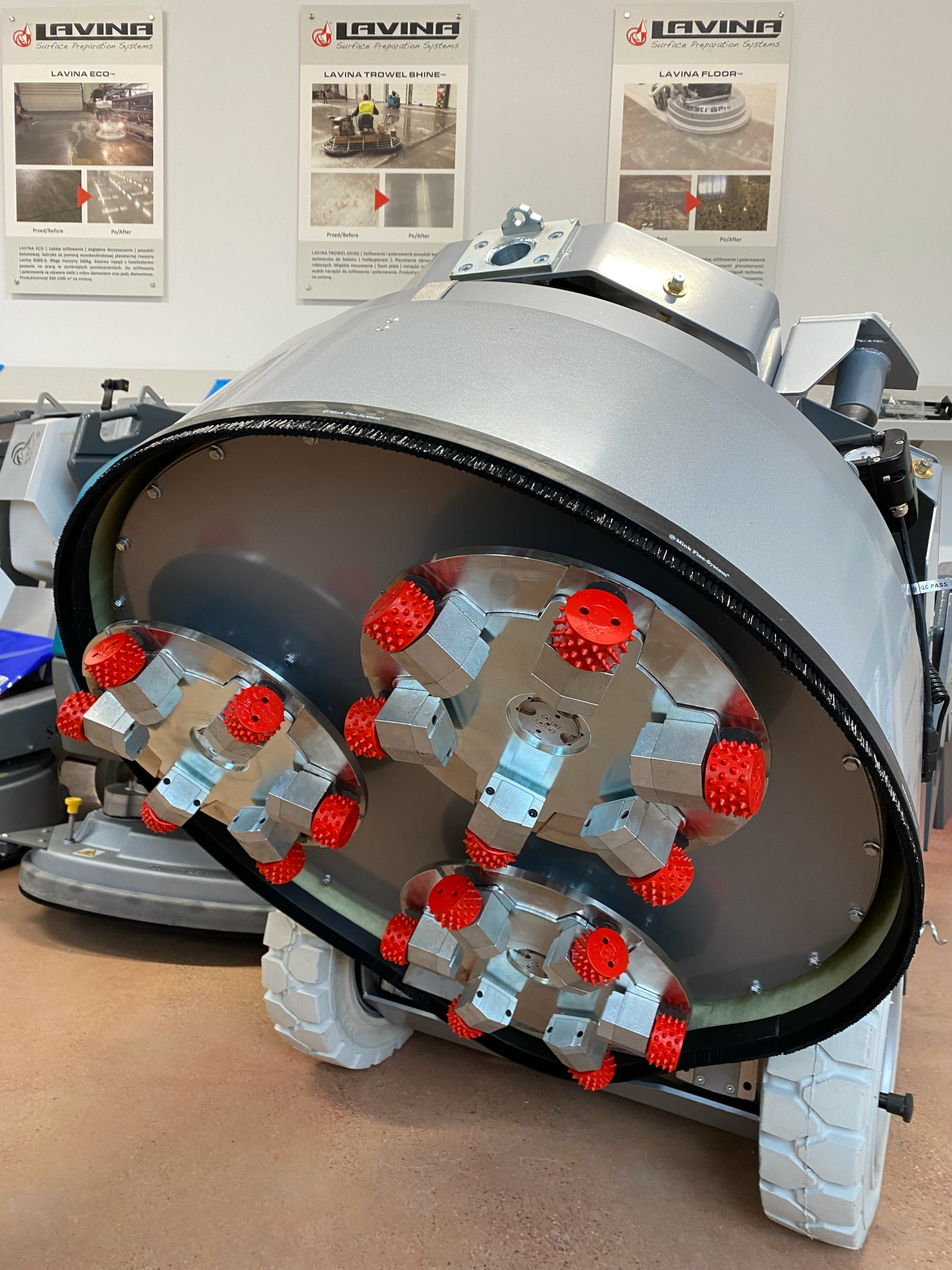

The technology of concrete polishing is a more and more frequent method of finishing concrete floors. Warehouse halls, industrial facilities, or large-area stores are places where polished concrete becomes more and more popular. What are the benefits of this technology?

Most of all, it is an inexpensive and relatively simple execution of a new floor. Then, the lowest costs of maintenance and easy regeneration of the already completed floor. This also means a decorative appearance and no additional top coat. Grinding and polishing of concrete floors is a step forward in the technology of floor finishing. Polished concrete can be delivered in three different technologies. Lavina Floor – by using heavy-duty rotary machines.

This technology allows for the deepest cut, and perfectly suits renovation of old and damaged floors, but also new, as apart from grinding it does excellent with polishing. Lavina Eco – slight cut, deep cleaning and polishing using high-speed machines, polishing screens and diamond pads. This technology is dedicated for slightly damaged and new concrete floors, where there is no need for deep grinding of the surface. Trowel Shine – polishing with trowel using adequate Superabrasive discs, adapters and tools. Trowel Shine technology is dedicated for new floors which should be restored to a polished concrete condition as soon as possible.

.jpg)

-2.png)