Marble Grinding and Polishing – How to Do It Professionally

Marble grinding and polishing is a process that requires proper knowledge, experience, and professional tools. To avoid scratches on the marble surface, it is crucial to use the right technique and always perform a test grind and polish on the target area. Scratches most often occur when improper metal-bond diamond tools are used.

Preparing Marble for Grinding

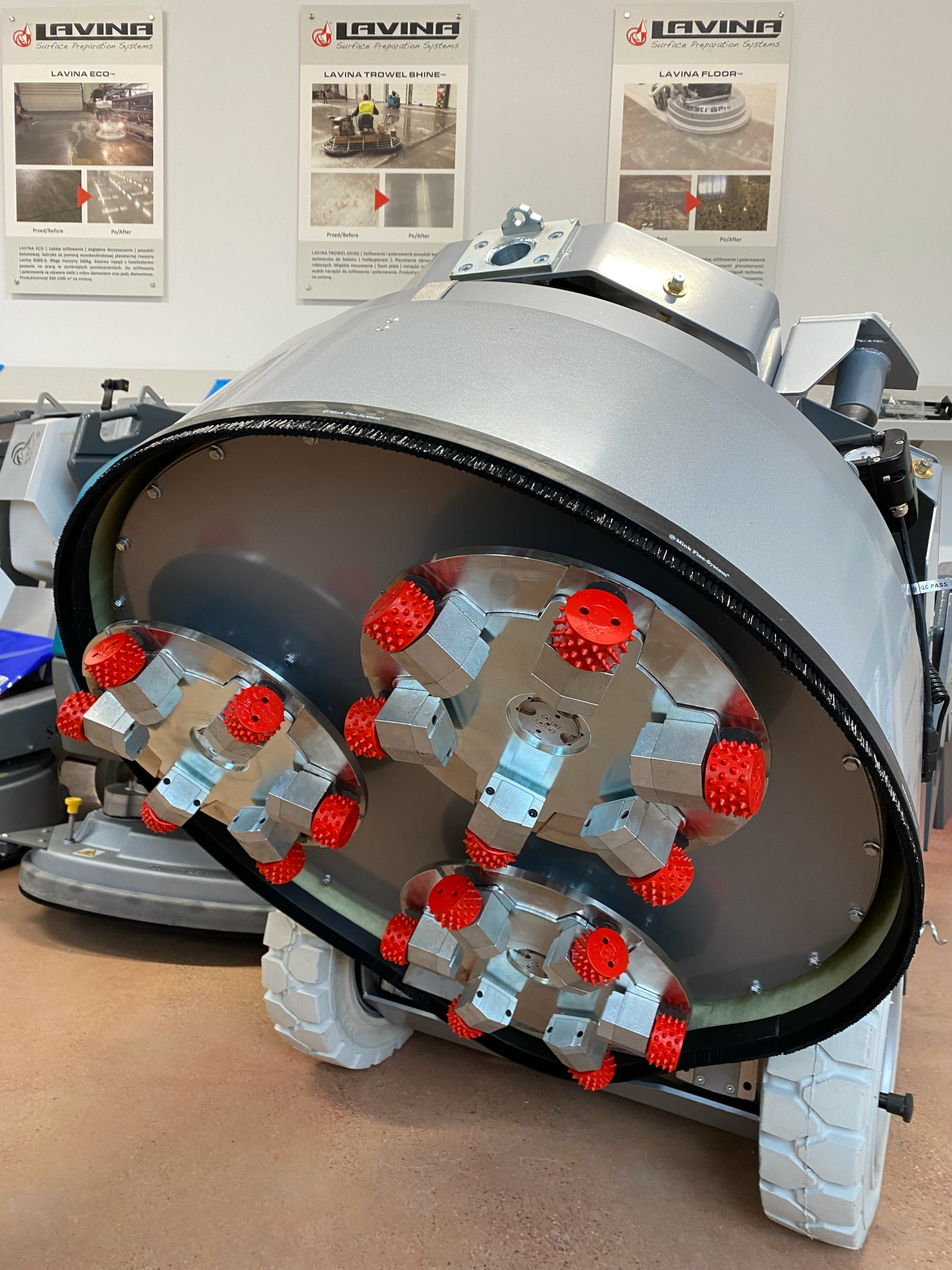

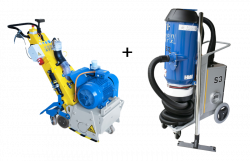

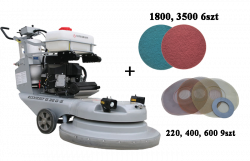

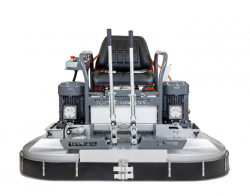

In the case of old marble floors or unevenly laid marble tiles, planetary grinding machines must be used for heavy grinding. This levels the surface and prepares it for further treatment.

Marble Grinding and Polishing Process

-

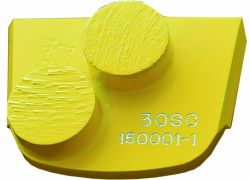

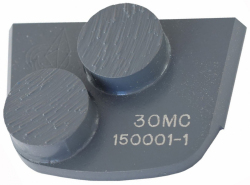

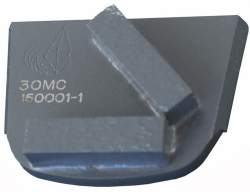

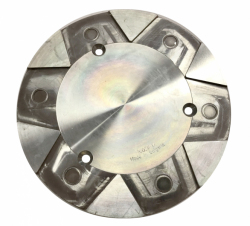

Initial grinding – using metal-bond diamond tools.

-

Honing and micro-scratch removal – with resin-bond diamond tools in grits: 50, 100, 200, 400, 800.

After grit 800, the marble typically achieves a soft natural sheen. -

Marble polishing – using:

-

polishing powders,

-

liquid crystallizer,

-

diamond pad or steel wool.

-

Polishing enhances both the gloss and hardness of the marble, and the proper use of chemical agents provides durability and a refined finish.

Marble Sealing – Final Protection

The last stage is marble sealing, which protects the surface from dirt, moisture, and wear. The final sealer should be buffed in using a high-speed machine with a soft pad – ideally one containing horsehair.

L30ES7

L25LES7

L25ES7

X2S-MC

-2.png)