These days dyes are extremely popular and we decided that the time has come to describe in details the method of applying dyes on a concrete floor during grinding and polishing

Ameripolish Surelock is a branch of liquid dye concentrates dedicated to coloring concrete floors and available in two packaging sizes - 0.23 and 1.15 liters.

1) Floor preparation

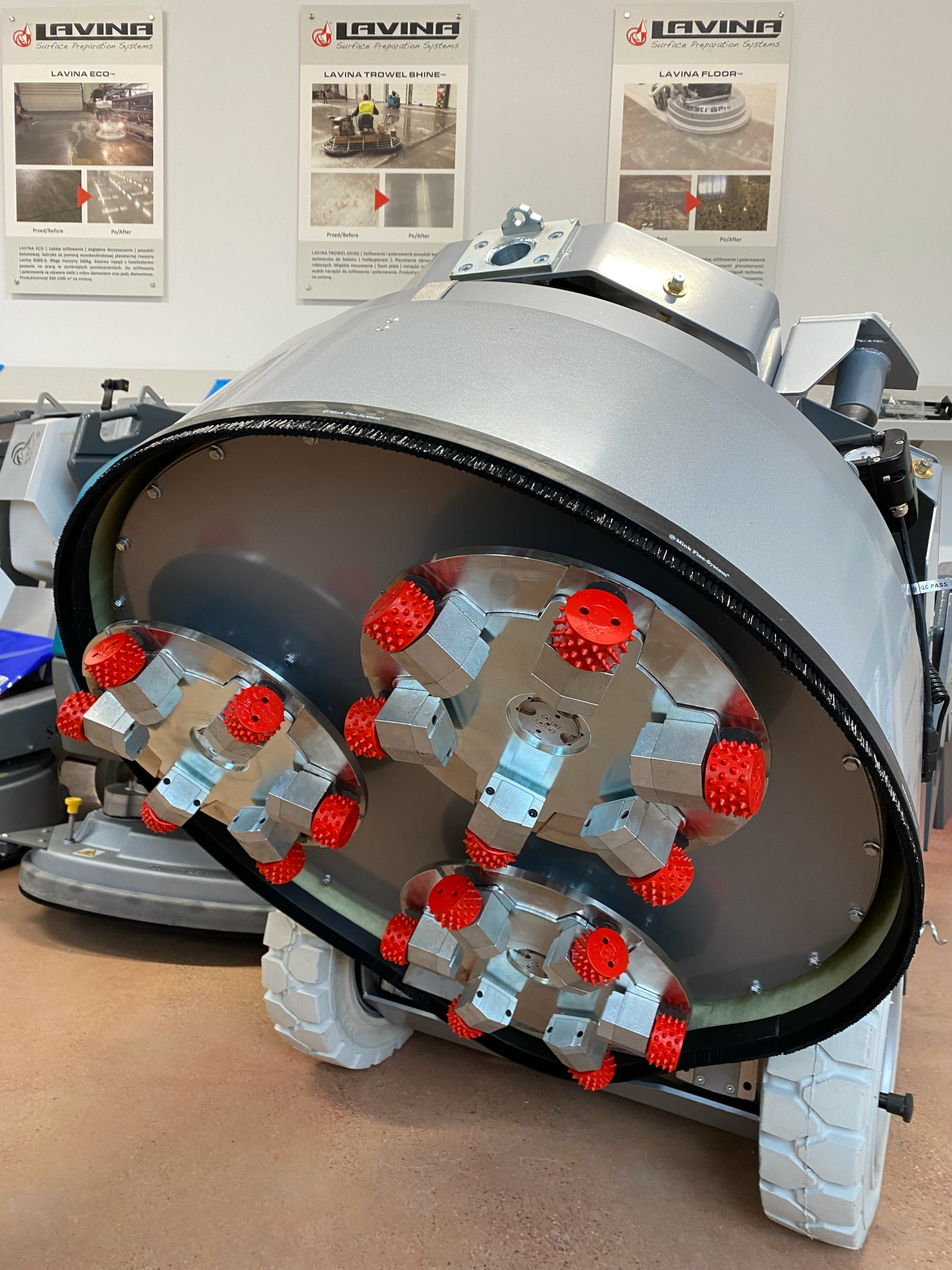

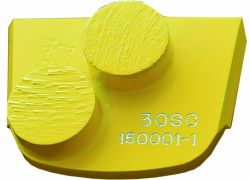

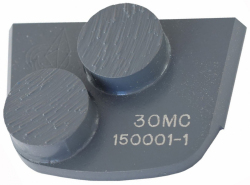

The concrete floor must be carefully prepared and grinded with XQC metal segments, adjusted to the hardness of the floor. Then the floor should be polished (till 200 grit) with Nato or WAFF plastic tools.

2) Cleaning

The next step is to clean the floor. We recommend cleaning the floor with Eureka or Tennant scrubber or using Lavina vacuum cleaner. The floor should be completely dry before applying the dye.

3) Dye preparation

While the floor is drying, you can prepare a dye

We dilute the 0.23 liter package in 3.6 liters of acetone or demineralized water

The 1.15 liter package is diluted in 17 liters of acetone or demineralized water.

4) Ameripolish dye application

Using a sprayer, we spread a thin layer of dye on the floor and then spread it with a mop (preferably a microfiber mop, which will not absorb a large amount of dye). This action can be repeated - the color will be more expressive

5) Drying the dye and removing the excess

You have to wait until the dye is completely soaked in the top layer of the floor. At a temperature of 15 degrees Celsius, we should allow the dye to penetrate (2 to 4 hours, depending also on air humidity and other factors). We remove excess dye with a clean mop or on large surfaces with a scrubber using a diamond pad (800 grit)

6) Hardener application (Ultralit Hard Standard Lithium Silicate)

After the dye has dried, its top layer should be protected with lithium silicate. If we have some dye left, we can mix it with silicate. To strengthen the floor, we recommend the use of ULTRALIT Hard Standard, which has excellent hardening and protecting properties of the dye. We apply silicate with a sprayer and a mop in the same way as in the case of the dye.

7) Polish the floor at the end

To preserve the effect, we recommend polishing the surface with diamond pads (400-3500 grit) the selection of pads depends on the gloss level you want to achieve.

8) Finally, we recommend protecting the floor with Ultralit Gloss Shield and polishing it with a high-speed polisher. Lavina B36G-S or Pioneer Amano Eclipse will be perfect. For both polishers, we recommend Suprashine High Performance diamond pads.

The above-described method should provide with the desired effect and give the floor an original, vivid, deep color and meet the investor's requirements.

As a reminder, we would like to point out that the efficiency of the concentrate and the color depend on many factors and these are only approximate values.

.jpg)

-2.png)