The Surelock concrete dye from the American brand Ameripolish provides excellent coverage and allows the concrete to be tinted with the desired color shade. The formula, refined over many years, has led to the creation of one of the most recognized dyes for concrete and polished concrete in the world. The product is available in a wide range of 24 different shades for an excellent aesthetic experience.

SureLock is easy to apply. The product is dedicated to be applied inside buildings, halls, shops and warehouses. Contrary to concrete paints, the dye penetrates the concrete structure and colors its upper layer.

Color: Sepia

0.23 l container is enough for coloring from 35 to 40 sq m

1.15 l container is enough for coloring from 180 to 200 sq m

Preparation:

1) Prepare the dye by mixing the concentrate with plain water or acetone

2) Concentrate ratio: 0.23l container + 3.6l water or acetone, 1.15l container + 17l water or acetone

3) Mix the solution thoroughly and pour it into the sprayer

How to use:

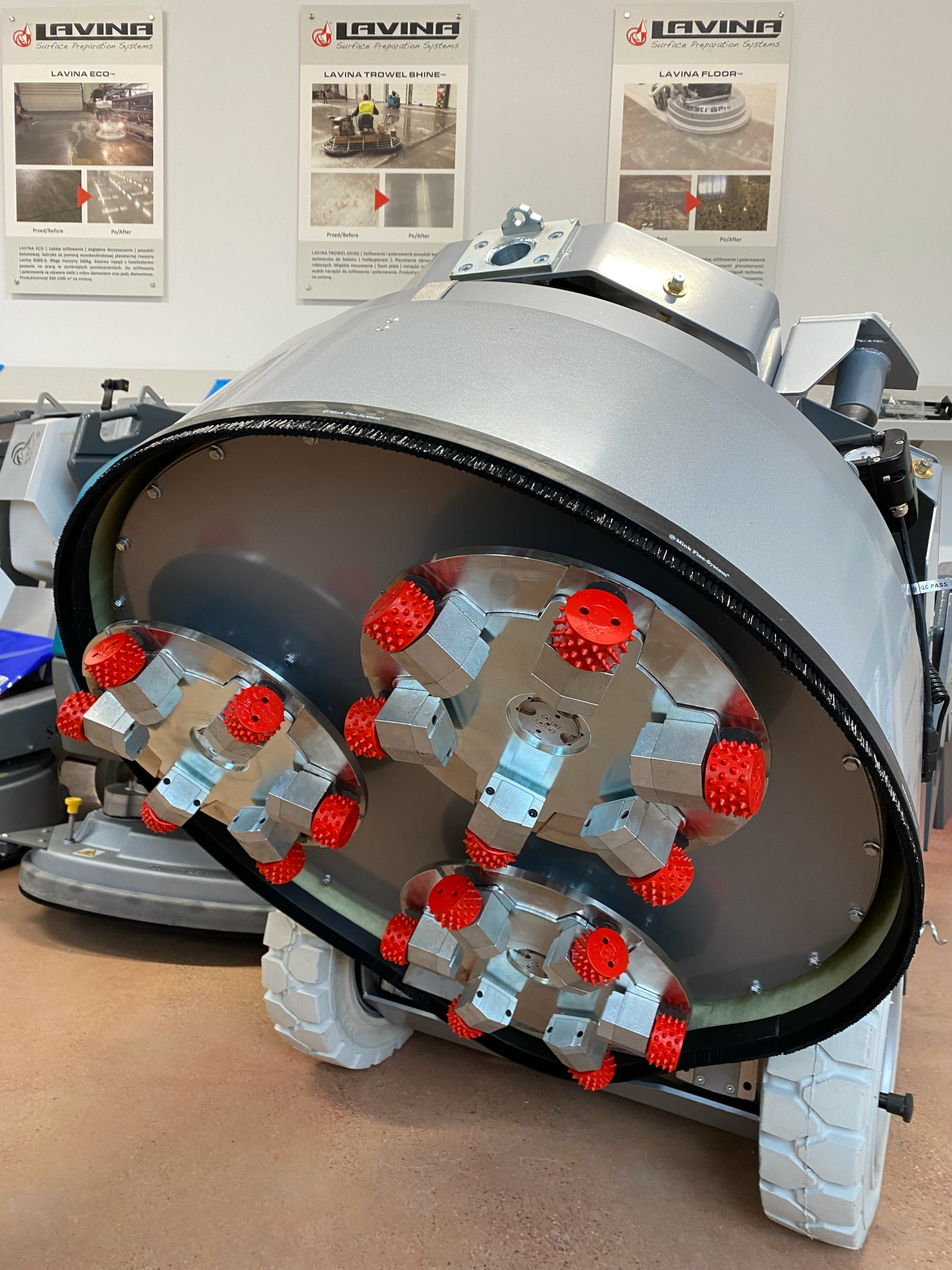

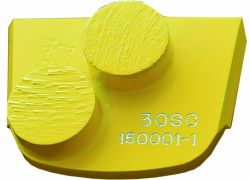

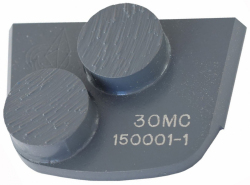

1) The floor, sanded with a metal segment and polished to 100 or 200 grit, should be cleaned and dried.

2) Spread a thin layer of the dye with a sprayer and spread it with a microfiber mop. 1 liter of the finished dye should be enough for 5-10 sq m. It is acceptable to apply the second layer of the preparation after the first layer has dried.

3) Wait for the dye to soak into the floor. At a temperature of +15 degrees C, wait no less than 2-4 hours.

4) After the dye is applied and the surface is dry, strengthen the surface with lithium silicate (eg Ultralit Hard Standard). It is permissible to add the remaining dye to the preparation containing lithium silicate.

5) After the lithium silicate has dried, polish the floor with a diamond pad (400-3500 grit (depending on the needs))

6) We recommend protecting the floors with a concrete impregnation containing polymers.

To ensure the best visual results, we recommend to cover the floor with Ultralit Gloss Shield, Gloss Lock, Matt Lock or Ultralit OWR after polishing the dye. The use of these impregnants will definitely improve the visual aspect of the floor (increase the color saturation) and extend the life of the floor.

Ask our specialist for support in choosing the final impregnation.

Pay your attention to:

- The manufacturer does not guarantee the concrete color in the RAL color palette

- The color palette is illustrative - the shade of the color may vary depending on the type, color and structure of the concrete. To check the shade on the target floor, it is necessary to perform a test.

- You should not use dye for a concrete floor with hardening sprinkles.

- You should not use dye on a dirty, oily, unpolished floor.

- Apply the dye to a well-prepared concrete for an appropriate gradation.

- Before starting the implementation, we always make a test and check how the dye will behave on a given floor.

- In case of staining failure, it is necessary to sand the top layer of the floor as the dye penetrates up to 2 mm inside the concrete.

.jpg)

-2.png)